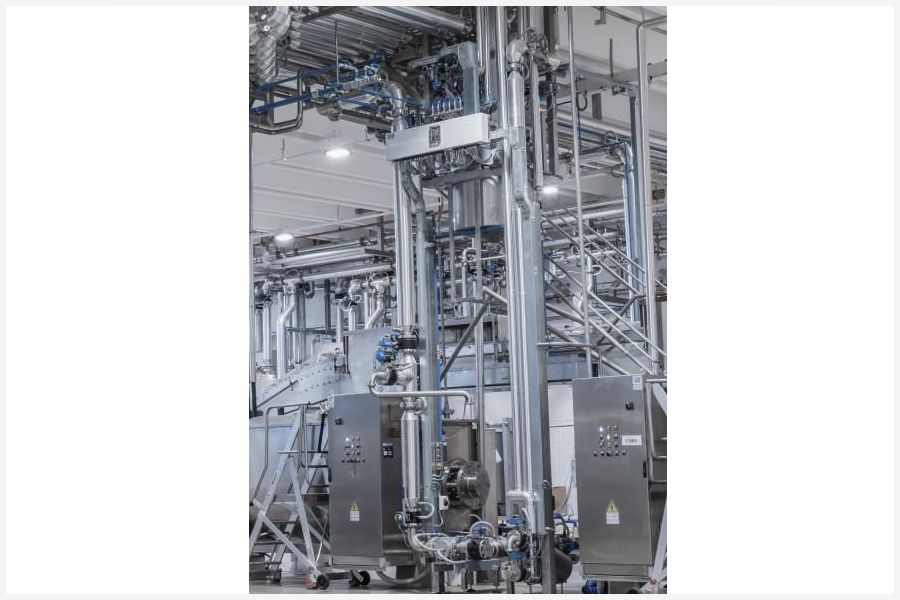

Fme offers a range of large tubular exchangers specifically designed to decrystallize chocolate obtained from pouring or molding machines. These exchangers are available in different sizes, allowing for customization based on the specific chocolate product, available hot water temperature, and layout requirements.

The primary purpose of these tubular exchangers is to facilitate the decrystallization process, ensuring that the chocolate reaches the desired consistency and texture. By efficiently transferring heat from hot water, the exchangers effectively melt and transform the crystallized chocolate into a smooth and workable state.

Fme understands that different chocolate products and production environments have unique demands. Therefore, the range of tubular exchangers is designed to cater to these varying requirements. The available sizes ensure compatibility with different batch sizes and production volumes.

In addition to accommodating different product needs, the tubular exchangers also consider the availability of hot water and the overall layout of the production facility. This flexibility allows for seamless integration into existing chocolate production lines, optimizing workflow and efficiency.

With Fme's tubular exchangers, chocolate manufacturers can rely on advanced technology to achieve consistent and high-quality results. The precise control of temperature and the efficient heat transfer mechanism ensure effective decrystallization, enabling smooth processing and enhancing the overall chocolate production process.