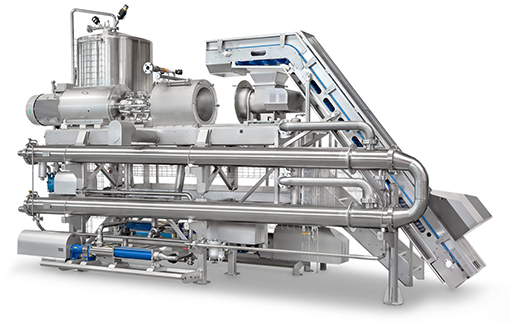

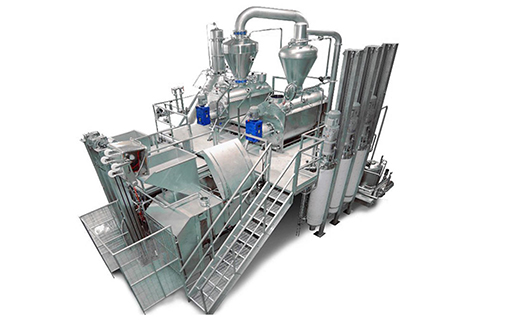

Fme is a leader in the creation of complete potato peeling lines that facilitate receiving, initial cleaning, pitting, washing, peeling, scalding, cooling and subsequent processing of potatoes.

Each process is meticulously tailored to suit the specific end product requirements, whether it be for fresh-cut lines, pre-cooked lines, IQF freezing, or French fries lines. At Fme, customization is a fundamental aspect of our approach, ensuring that our solutions align perfectly with your desired outcomes.

Each line is configured to handle the necessary steps such as destoning, washing, peeling, blanching, and cooling, with precision and consistency. By integrating cutting-edge machinery and automation systems, we streamline the potato processing workflow, saving time, labor, and resources.

We prioritize efficiency and sustainability in our process line designs. By optimizing energy consumption, water usage, and waste management, we strive to minimize the environmental impact of our solutions. Our commitment to sustainability extends to the choice of materials and technologies that promote resource conservation and reduce emissions.

Experience the difference with Fme and take your potato processing to new heights.

Talk to our experts

Connect with our team for tailored solutions! Contact us.